Best Baby Friendly Vacations for the Entire Family

Traveling with a toddler is an exciting adventure and finding the perfect destination is the starting point. We’re exploring three destinations that cater to the needs of the whole family,...

Free Shipping* on orders over $59! See details

Since 1917, our family-owned company has built a legacy of innovation and quality with a mission to create smiles and warm memories that last a lifetime. From the beloved little red wagon and classic red tricycle to thrilling go-karts and adult ebikes, we have evolved our brand and product offerings to continuously create the best outdoor toys for kids and design world-class products that serve the whole family. From childhood through adulthood, Radio Flyer unites generations of families with active toys and products that deliver smiles and create warm memories.

Certified leader in the global movement for using business as a force for good

We're a 3rd generation, Chicago-based family owned company

Delivering beautifully designed, quality products since 1917

Certified leader in the global movement for using business as a force for good.

A 3rd generation & Chicago-based family company.

Delivering beautifully designed, quality products since 1917.

Traveling with a toddler is an exciting adventure and finding the perfect destination is the starting point. We’re exploring three destinations that cater to the needs of the whole family,...

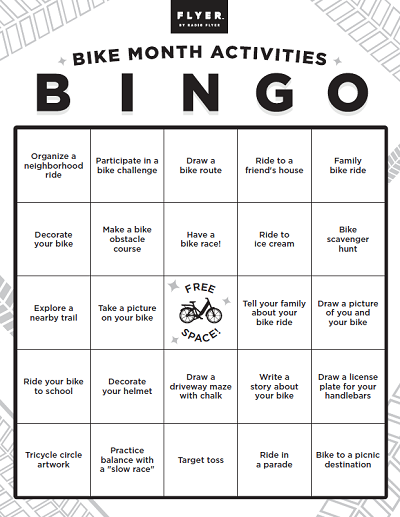

Celebrate Bike Month this May with these 25 bike activities for kids! These are perfect for beginner riders with tricycles or big kids who are seasoned bikers. Print out this...

Ready for summer fun? Download this free printable bucket list for fun activity ideas to inspire active adventures and creative play this season. Plus, the free printable doubles as a...